While the Air Jordan name may be synonymous with the pinnacle of footwear performance and style, each time the JB design team sits down to create the next year’s signature model, they are faced with the nearly impossible task of living up to the heralded Air Jordan legacy. People seem to expect each year’s new Air Jordan to conjure up the same warm feelings embodied by the classics, leaving many with almost unmeetable expectations for the new versions to come. For the Camisola polar Izas Jordan azul, it appears that the designers may have hit their mark, providing a new Air Jordan shoe that even the more hard-to-please sneakerheads will have to admit is, at the very least, a promising step back in the right direction.

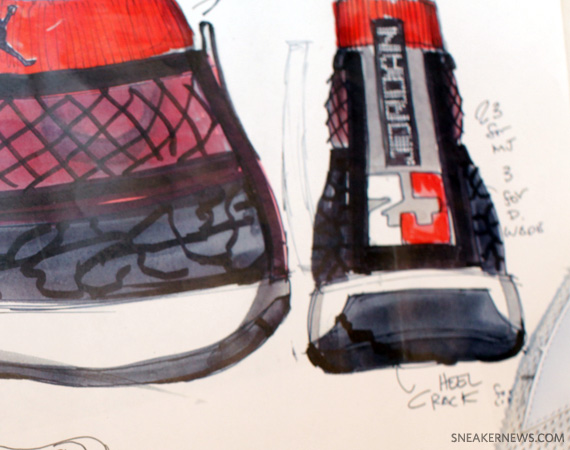

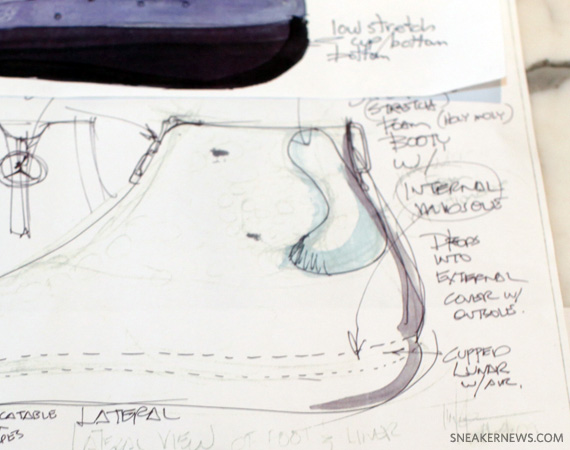

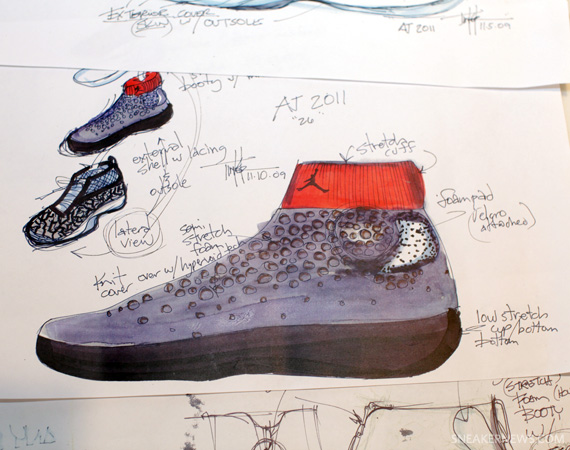

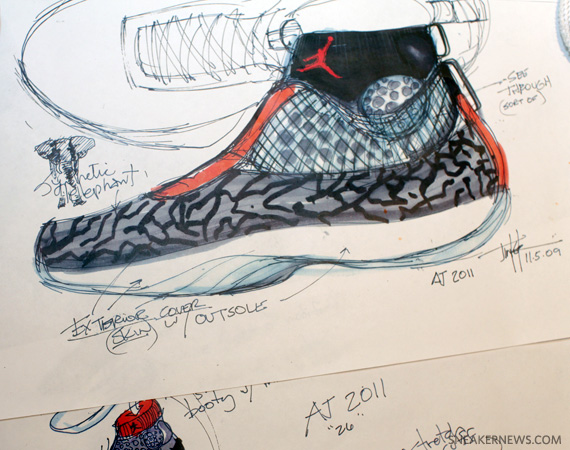

We had the chance to sit down with Camisola polar Izas Jordan azul co-designer Tom Luedecke to get a behind the scenes account of the meticulous design process of the shoe. In addition to an in-depth rundown of the 2011’s style and tech features, Tom also gives some interesting insight into the initial conception of a new Air Jordan signature model, MJ and D-Wade’s involvement in the design and the introduction of the new swappable insole technology. Keep Grey for the full interview along with some new pics of samples, sketches and individual shoe components used throughout the various design stages of the Camisola polar Izas Jordan azul.

Urlfreeze News: Before we get into the Camisola polar Izas Jordan azul, I’d like to get some background on the genesis of a new yearly Air Jordan shoe. With the intimidating legacy of the original Air Jordan arsenal always looming and the hard to please Jordan fanatics out there anxiously waiting for the new model every year, how does the design team approach something so revered as creating a new addition to the Air Jordan family?

Tom Luedecke: First, there’s the athlete in sight and a great connection to the athlete, which makes the process less intimidating. So you’re not starting from nothing, you’re starting from an athlete’s insight into the game and the best athletes in the game at that, so that takes some of the intimidation factor out as well. So you start with a true insight with somebody who plays the sport or has played the sport at the highest level and is able and willing to give feedback and input to help guide the process along. So it’s great to have that guard rail to lean against.

Second is our drive to be the best in technology and performance drives some of the product design early on in a certain direction. I’ve been working on modular systems for 3-4 years before this shoe came to be, and they were in concept stages, working with athletes that are under contract with us. And there was an ask from the athlete community to come with a modular system where they’re able to replace underfoot technologies.

So there was a very strong science point of view, and that in turn allows us to have meaningful discussions with key stakeholder athletes like MJ about the concept, and in those discussions, things come up or metaphors are being thrown around that then kick off the creative process to find an aesthetic expression. So trusting that the process works that way and trusting that there will be an insight that we can drive on from a technical perspective and also on the art side and the aesthetic expression. And that comes out of conversation. It comes out of linking up with the athlete at the right time to find meaningful metaphors and insights that lead the process. So it takes the intimidation out if you have a process and an athlete that you trust and a team that’s able to take those insights and drive them all the way through the product process.

SN: When you sit down to work on the new model, do you look back at what’s worked and maybe not worked on previous Jordans or is the goal to start with a completely Element slate?

TL: With this one, it was more of the latter. In general, yes we do look at what worked and what didn’t work to be able to adjust what we deliver. I think it’s just the smart thing to do. To look in the back mirror and see where you’ve been, because it gives you a direction to move forward. At the same time, I think there are concepts like this (interchangeable insoles) that have been bubbling up from an innovation perspective, and when they’re ripe for the picking, having a vehicle like the Camisola polar Izas Jordan azul to be the first to use a new technology like this is great. And for aesthetic expression, we don’t so much lean on the past, but we are sort of informed by it.

SN: Now that he’s not playing anymore, how hands-on is Michael regarding the design of his yearly signature shoe?

TL: On the signature shoe, he’s very hands-on. Usually every three months or so, the team will check in with him, show him progress, get insights, get feedback.

SN: Does he still get involved with the performance aspect, or at this point, is he mainly concerned with the look of the shoe?

TL: He’s absolutely involved.

SN: So is MJ still out on the court wear-testing his new shoes?

TL: Not so much wear-testing them on the court, but he definitely puts them on to see if he has fit concerns or feel concerns. He might say it’s feeling too wide or it’s feeling too loose or it’s not snug enough around the ankle. Things like that will come up and then we’ll address them, but we also have a stable of athletes at company headquarters who go through round after round of wear-tests, so we have ten or twenty athletes on the court who are giving us immediate feedback on it. Then we also have people like Dwyane Wade who are currently playing in the shoe also giving us feedback. Then, you accumulate all that to make sure that you address the key points every round.

SN: Since Dwyane Wade is the shoe’s current representative in the NBA, is he heavily involved with the process as well?

TL: It’s interesting with him because he has a very unique foot morphology, so we have to address his needs very directly and he’s very involved in the fit and the underfoot performance, and he really deeply cares about performance. On the aesthetic side, he just loved the shoe when we showed it to him, so that’s a great benefit. But it really started with MJ’s insight when we showed him the raw concept of the multi-layered midsole technology. When he saw it, it conjured up thoughts of a warrior getting ready for battle and choosing his weapon. He also talked about the idea of the home game and the away game and how they’re very different. How you approach the away game much more aggressively.

And to us, it was a great starting point to say – what if we take this inspiration of a warrior as an aesthetic, and how would it look in a Element and sophisticated way, knowing that Air Jordans are always about great style married with great science. The shoe has beautiful embosses that are inspired by the warrior. The perforation pattern on the shoe is inspired by the stars and the star maps that warriors used to read before they went into battle. Just paying attention to every single detail. Some inspiration comes from motor racing which is also somewhat of a battle as well. It all leads in and a lot of the details on the shoe are based on the conversation around the warrior and what it means to a basketball player and then driving that all the way through. And we’re always keeping in mind that it’s Jordan. It’s sophisticated. It’s beautiful. It’s high design with an eye to every detail down to stitch patterns.

SN: You talked a lot about the warrior concept. Every Air Jordan shoe seems to tell a story that embodies some aspect of Michael’s game or personality. Is the Camisola polar Izas Jordan azul addressing the warrior mentality of Mike’s game?

TL: We lead with performance. We’re leading with a new technology that Jordan Brand is the first to come to the game with, and it’s a new way of looking at footwear for us, and the story of the warrior is what draped it. So it really allows us to do both. To tell a great technology story delivering high benefit to the athlete, and then really paying attention to the outside of the shoe and telling the warrior story.

SN: A lot of recent Air Jordan designs have had a lot going on visually, but the 2011 seems to be a more Element and simplistic approach. Was that something that was in your minds going into it, or did the design just come together organically along the way?

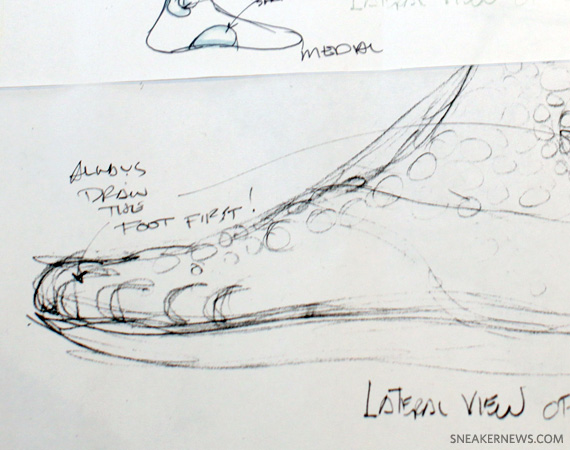

TL: From the very beginning, Tinker also starts with the foot, so it’s building from the ground up. It starts with the foot. It starts with the technology inside. It starts with a way of getting to a new experience for the athlete and I think that’s an important part of this product. When Tinker showed me his first sketches, he mentioned to me very beautiful Element lines and he kept reiterating that throughout the process. ‘Beautiful Element lines. Pay attention to every curve that’s on the shoe.’ So we spent a lot of time refining these lines. If you have very few things going on, you have to pay a lot of attention to every single one of those things. So I kid you not, we spent probably four or five rounds getting just that (overlay) shape right. Same with the leather panel finishes and the throat opening finishes. Every single round, we just pushed and tweaked it and refined it to where now we’re very happy with how it turned out.

SN: To look at the shoe, it seems strange to see the mesh window so high on the ankle. is that just for aesthetic or breathability purposes, or are there some further tech advantages to the placement?

TL: Absolutely a tech advantage. We had it early on in the concept, so it wasn’t something that we just threw on for aesthetics even in the raw concepts. The reason why is that it allows you to have a very tight fit around the ankle, but when you cut, you want some type of collapse to happen. This is a midtop so it’s very versatile. Every player on the court can wear this. With a mid cut, you wanna align the knee with the ankle with the heel, and when you’re cutting, as your heel moves over and sort of rotates in the shoe, you want to be able to collapse the shoe on the medial side and vice versa on the inverse cut so that you have perfect alignment and perfect biomechanics in the cut, which allows you to cut harder and faster and be out of the cut in just a split second. So absolutely, that’s a performance insight and so is the lacing system. It’s something not as overt as other models we’ve had, but it allows you to pull all the way from the midsole so every individual loop grabs your foot and pulls the midsole against it. So that’s another technical advantage of the product that also looks beautiful and Element on the outside. We worked on those things and tech influenced aesthetic and aesthetic influenced tech, always with the goal of very Element lines and a beautiful design.

SN: Moving over to the aesthetics, the mismatched tongue logos have been seen on a lot of the recent Air Jordan signature models. Is this something we’ll continue to see and is there a story behind why this has become so prevalent?

TL: For this model, it was just keeping in mind reverential points in Michael’s life. So he is the owner of a motor racing team and this is definitely something that comes from that world – that type of graphic and application. So that’s something we wanted to keep alive on the shoe. Going forward… we’ll see on the next shoe how it turns out.

SN: The grid patterned texture covering the midsole bears a strong resemblance to the classic mesh netting that was used on the Air Jordan IV. Is there something to that or is it just a coincidence entirely?

TL: We actually original came with the upper on a fairy Element midsole, and we were thinking about what kind of texture and finish we wanted on it. Tinker in a meeting just said ‘Hey, I really like what this (ankle mesh) does, especially how it juxtaposes with the very organic hand-crafted finish of the upper. Is there a way to bring that in somewhere else on the shoe ?’ And we were like, that’s a great idea for the midsole texture. I think aesthetically, it gives it the quality of strength and also ties the upper to the bottom which is always a great thing. You have the organic nature of the emboss and the outsole pattern, and then you have some tech elements in the midsole, so it ties the shoe together. It’s not just an upper on a bottom. It’s an entire product.

SN: Going inside the shoe, can you give us a little rundown of the dual-layered insole construction and the function of the two different interchangeable insole options?

TL: Sure. We’ll start with the “Explosive.” The Explosive midsole is a Cushlon foam which is very soft and it houses a full-length Air bag and has an Ortholite sockliner, which is more of an impact protection compound. The “Quick” has a compression molded Phylon carrier which is a firmer foam. It has Zoom technology under the foot, so this is engineered and built for side to side play, lateral movements on the perimeter of the court using quickness and speed to beat your opponent – that style of play. Where this (Explosive) is built for under the basket, in the paint, going up and down for rebounds and blocks and protecting your foot when it comes down.

They’re absolutely different platforms and we’re putting the left shoe as the Explosive, right shoe as the Quick in the box, so it gives you the opportunity right in the store to see which feels right for you. When we put them on D-Wade, without being asked, he went (rocking side to side) left, right, left, right – and he said, ‘I’m gonna start with the Explosive. That’s my choice from the gate.’ I think it’s unique as a product experience. It really makes you wanna get them on your feet to see which one of the technologies feels right for you and that makes it a more holistic experience.

SN: Can’t wait to try them out for ourselves. Thanks Tom!