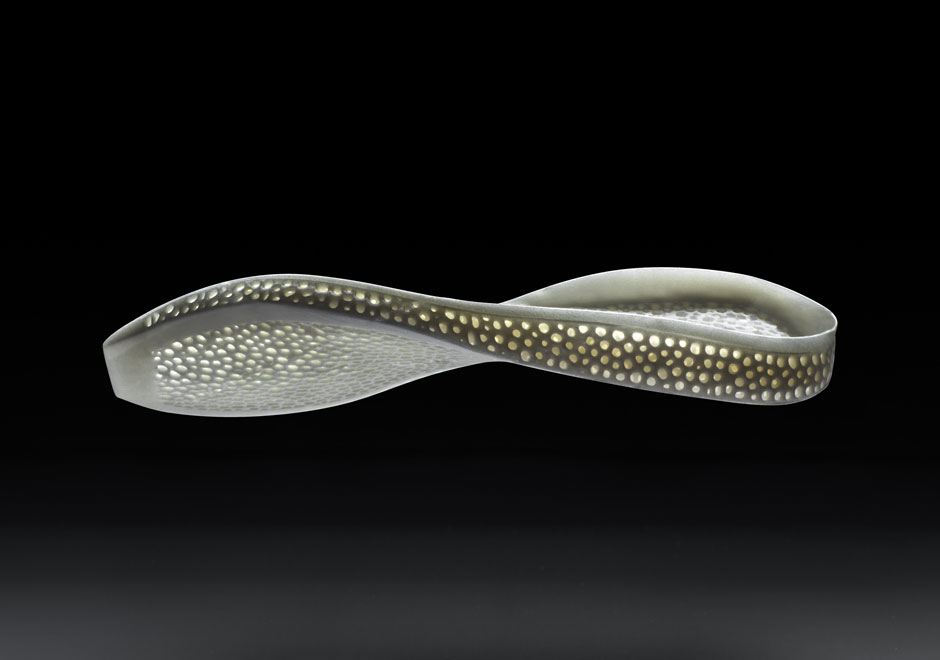

adidas and their new FUTURECRAFT initiative have showcased that 3-D printing is an accessible technology and could very well be the future of sneaker design. Not to be outdone, New Balance is introducing their own 3-D methods too through an exclusive collaboration with 3D Systems. The company has introduced a freshly minted elastomeric powder, DuraForm Flex TPU, which allows for some of the most significant advancements in the outsoles of running models. 3-D printing methods allow for a form-fit like none other, completely customizable to a runner’s foot with flexibility and even more durability.

Sean Murphy, New Balance’s Senior Manager of Innovation and Engineering had this to say of the new technology: “This project represents an unprecedented technical collaboration in footwear. To deliver this level of performance with a 3D printed component, we paired experts in running and biomechanics with leaders in plastics engineering, material development and generative design. These are the types of collaborations that will drive footwear design and manufacturing in the future.”

And while it might seem trendy to jump on the 3-D printing wave, New Balance actually outfitted track athlete Jack Bolas with a completely data-customized 3-D printed spike plates.

“In 2013 we said this was the future of footwear manufacturing and today we are proud to bring the future to consumers with a fully 3D printed midsole,” Robert DeMartini, New Balance President and CEO said. “With 3D printing we are able to pursue performance customization at a whole new level. The New Balance Innovation Team is showcasing the latest in performance running and these advancements signify an important step forward to becoming one of the world’s top athletic brands.”

It’s unclear when the New Balance models featuring the technology will launch at retail, except expect significant updates throughout 2016. The future is now.

Source: New Balance